|

| Here is a simple Bolt Hardness Chart and the Identifying markings, you can easily find more complete charts by searching "Bolt Hardness Chart" |

|

| In this side view you can see the lower mounting bracket that was replaced due to the grade 8 bolt wearing out the mounting hole. |

|

| There was also some significant wear on the Grade 8 bolt. |

|

| Here is the Power Transfer switch at the electrical panel to switch from shore to ship power. |

|

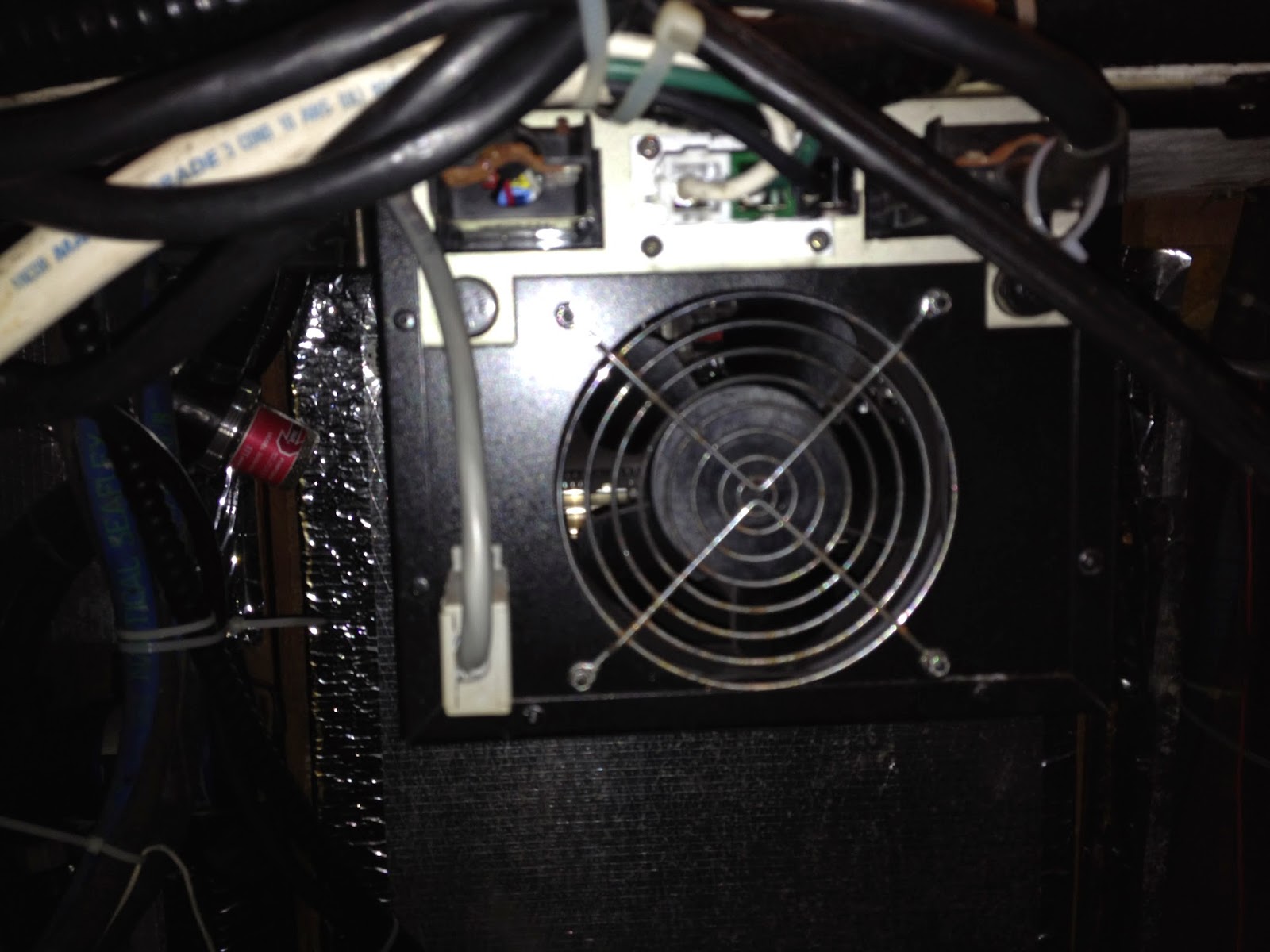

| This is the AC Unit where all the connections are made from the Seapower unit and to all the control switches. it is mounted just above the engine in the engine room |

|

| AC Unit side angle view |

|

| Schematic of the Seapower wiring from the owners manual |

|

| Part description page from owners manual |

There always has to be a winter project if you own a boat. If there is no winter project/s then you are a worthless boat owner for sure. Boats require constant attention and if you fail the test then you will pay at the very worst moment. Boat projects for the winter vary as much as the boats and their owners themselves. You can be sure there is a pressing need and if you live by the Hear No, See No, Speak No then when you are at the farthest point from help and in the worst weather, with a boat load of seasick crew the Caca will hit the fan and Poseidon (or Neptun if your in fresh water) will raise his ugliest head.

One of the systems on the boat when we bought her was a 5 Kilowatt SeaPower System. I had never heard of them before since all the sailboats we had experience with either had no AC (120V) power or they had a generator on board. What I have learned about SeaPower units are they are usually installed on power boats since they have large engines that are always running and can manage the load they put on the primary engine. The smaller Coast Guard Vessels use them rather than add the weight of a generator. The non-marinized version are also used in lots of vehicles like ambulances, work trucks etc. Even after we bought the boat I was not sure if we would keep it or buy a regular generator to replace it. As luck would have it we got to meet and talk to the previous owner who had the unit installed. He really liked the unit and told me that when they had his mother on board she would go below and turn on the Air Conditioning when she had enough of the Texas heat. First time I had ever heard anyone sailing in the Air Conditioning! Anyway, he explained how handy the SeaPower System was and they did not have to maintain a separate engine just for AC power. For just day sailing in the bays there really is no need for any type of AC power so I justed tested the unit out a few times to see it work. It runs both the forward and aft 12,000 BTU Air conditioners or one Air Conditioner and the Microwave. Not really knowing how often we would need AC power as cruisers I decided to just keep it and go cruising. If it did not work out then deal with replacing with a generator then.

When we were cruising and before we had solar panels we had to run the engine two hours a day to charge the house batteries. So we split the time, one hour in the morning and one in the evening. Since we could turn on our 110 volt battery charger we could easily top off the batteries in an hour. Additionally we could use the AC power for cooking coffee and breakfast and then for dinner in the evening. The system worked just fine for us and I am glad not to have another engine to maintain. Now since we have solar panels we only need to run the system occassionally for short periods when on the hook. The longest we ever ran it was to power my Hooka compressor for cleaning the bottom which could take 3 hours and was a monthly chore in the Southern Florida waters.

On our 7 day return trip across the Gulf from St. Petersburg to Corpus Christi we would run it for an hour around 0200 since the combined use of all the electronics and especially the power hungry Navionics Auto-pilot would bring the house batteries down to a point where caution on the side of safety came the rule.

I talked to Don Glandt of Gulf Stream Marine who is the best goto guy for electrical and engine work in Corpus Christi and he said when these mobile power units came out in the early 90's for boats, they were very popular on smaller sailboats who did not have room for a on board generator. He said it was a huge mistake for the smaller sailboats since the unit takes a minimum of 5 horse power to run so the smaller engines had problems managing the unit. One 11 horsepower diesel engine even had a bent shaft due to driving the unit while the boat was motoring along. They are definitely not meant to be an option for smaller engines. It was clear that Don favored a regular Diesel Generator to the SeaPower systems.

When we are unable to get the boat out sailing on a regular basis then I substitute running the engine in the slip with the transmission in reverse since diesels do not like to sit for long periods of time (hoping it will direct some flow against the hull and provide some bit of cleansing). Last November I noticed a noise/vibration, I was hoping it was not due to shell build up on the prop, but that would have been a lot cheaper to resolve. I opened the engine room doors and looked around, it only took about a minute to realize it was coming from the Seapower unit mounted on the forward/port side of the engine. I knew what is was since I had already experienced this once before when we were in St. Petersburg, Florida staging for a Gulf of Mexico Crossing back to Corpus Christi. It took a bit longer to isolate the problem then but since I had already had to replace the lower mounting bolt on the unit I knew that it must be the source of the noise/vibration. In Florida I took the bolt out and it was worn so bad that I decided to install a much harder Grade 8 bolt that could last longer and possibly resolve the issue for good..What I did not realize is that I had installed a bolt that was harder than the bracket it fit into. This resulted in a rounding out of the bracket which is part of the front collar of the unit.

Fortunately the E42 has lots of engine access and It is simple mater of taking two bolts out and the duel V-Belts to remove the unit from the engine. In Jan/09 I had sent the unit back to the company in Dallas to have new bearings and brushes installed which cost $259.14. I did not know it at the time but the unit was a 1996 model so I am sure it needed the work especially before we started out on our Gulf of Mexico cruise to the Florida Keys. The company had changed hands since I had last needed repair work and thank goodness for the internet it only took a few searches to find the new company now in Garland, TX and their technician Gary. When Gary asked for the serial number and he told me it was a 1996 unit. I knew I would be lucky if they could put on a new bracket. He said to send it to him and he would let me know when he saw it. Just a few days later Gary called and told me he could fix it up. $441.93 later and he sent it back. The fit was so tight on the bracket I had to get a file out and take a few swipes, now it fit snug and with the softer grade 3 bolt I hope to manage the maintenance of the unit more closely. The bracket has been greatly improved over the old one as it has removable sleeves in it so that if there is any wear you can easily just press in a new sleeve, a new bolt and keep on cookin'!

The question I feel many might ask is would I rather have a 5Kw generator instead, and the answer is No, the SeaPower Unit is working just fine for our style of cruising and the little bit of hassle I have had so far keeping it running is no where near the level of maintenance another complete engine would ask of me.

You can see the Mobile Power Website at http://www.meps.com/ and the SeaPower unit at http://www.meps.com/New_Site/Documents/New_Items/Products/SeaPower_Brochure-kVA.pdf

No comments:

Post a Comment